If you’re used to off-road activities, it’s just a matter of time before you’re stuck in a ditch, mud hole, sand, snow, or God knows what else. In most cases, it’s the winch that comes to the rescue when your fancy 4-wheel drive can’t save you.

But you’re not going to pull out of that sticky situation if you don’t know how to properly use a winch, can you? Even if you do, it’s important that you follow all the safety precautions because if you’re negligent, a winch can cause serious injury.

Lucky for you, this is the know it all ultimate winch guide. We’ve done our homework to tell you everything you need to know about using a winch.

No mumbo jumbo, let’s begin.

Basic Parts Of A Winch

If you break down a winch into different parts, this is what you will get:

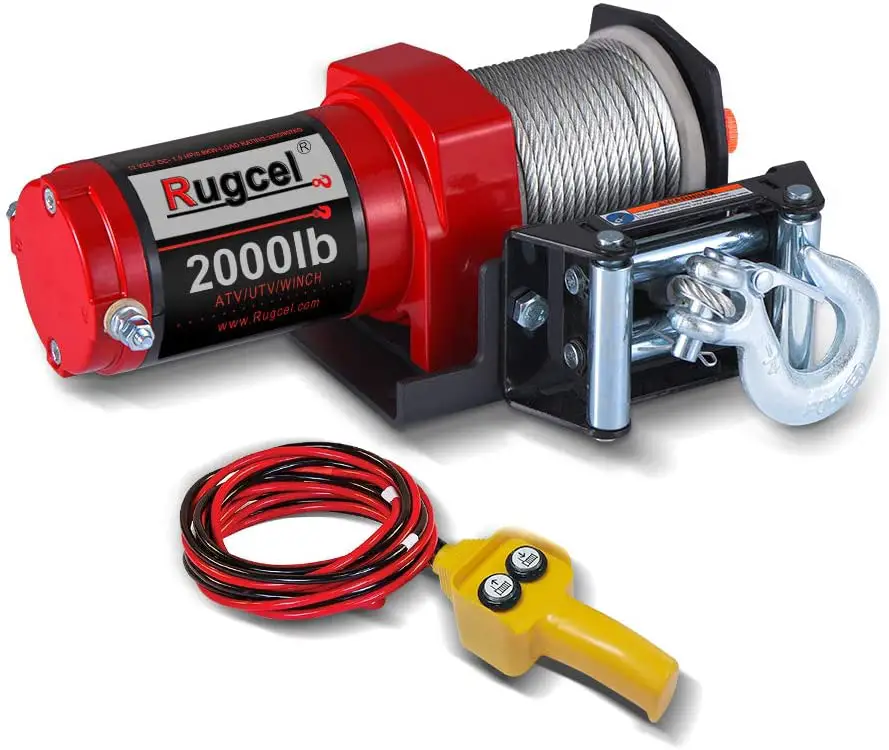

1. The Winch Motor

The motor is like the heart of a winch; it’s usually connected to your truck’s battery, and it channels the power to the drum. However, the motor on a hydraulic winch control is not connected to the battery but instead, it relies on the steering wheel pump to function.

2. The Drum

Once the power is channeled into the drum, it rotates to draw in the cable around it. Basically, the drum is the cylinder part that sucks the rope. Comprende?

3. The Cable aka The Rope

Call it what you want, but the rope or the cable is enfolded on the drum and looped to a supporting object to recover your vehicle.

Buy The Cable aka The Rope On Amazon

4. The Fairlead

This is usually an overlooked component, but it’s the small opening that the rope is fed through during a recovery maneuver. The fairlead protects the bumper and cable against damage.

5. The Gear Train aka The Transmission

The gear train works by converting the motor’s horsepower into torque.

6. The Braking System

When you need to slow down the winch drum, it’s the braking system that does the job.

Buy The Braking System On Amazon

7. The Clutch

The clutch is used to manually engage and disengage the winch drum from the gear train. Hence, you can use the clutch to free spool the drum and lock it back in.

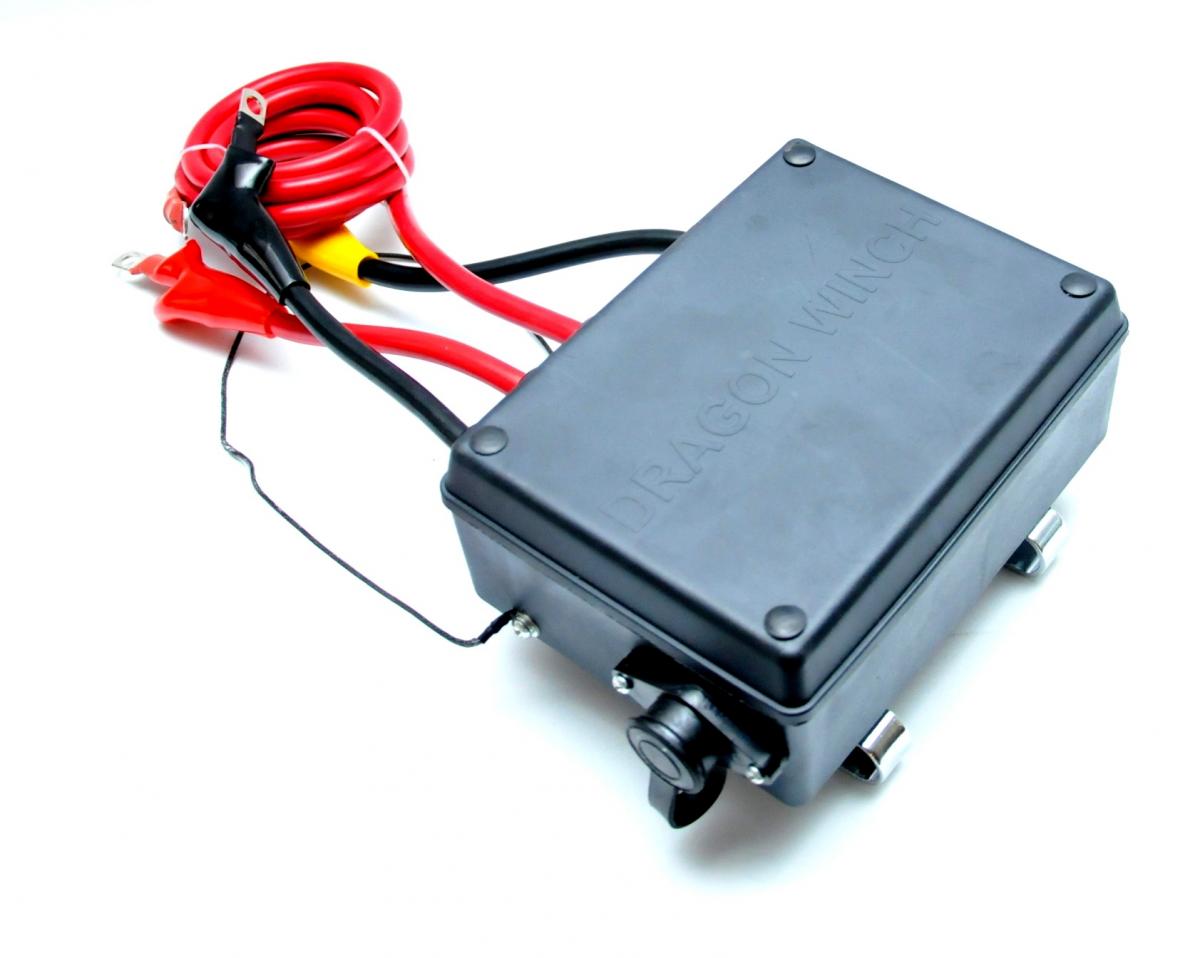

8. Control Box

The control box is sort of an intermediary between the remote control and the motor whenever you want to change the winch drum rotation.

Buy Winch Control Protection Box

9. Remote Control

The remote control is used to adjust the speed, direction, and power of the winch from a distance. It could be a wired or a wireless remote control.

Buy The Remote Control On Amazon

Basic Winch Accessories

Before you get started, you will need the following accessories to get the job done:

1. Gloves

You’re definitely going to need gloves especially when you’re dealing with steel cable. You don’t want to get bruises on your hands, do you?

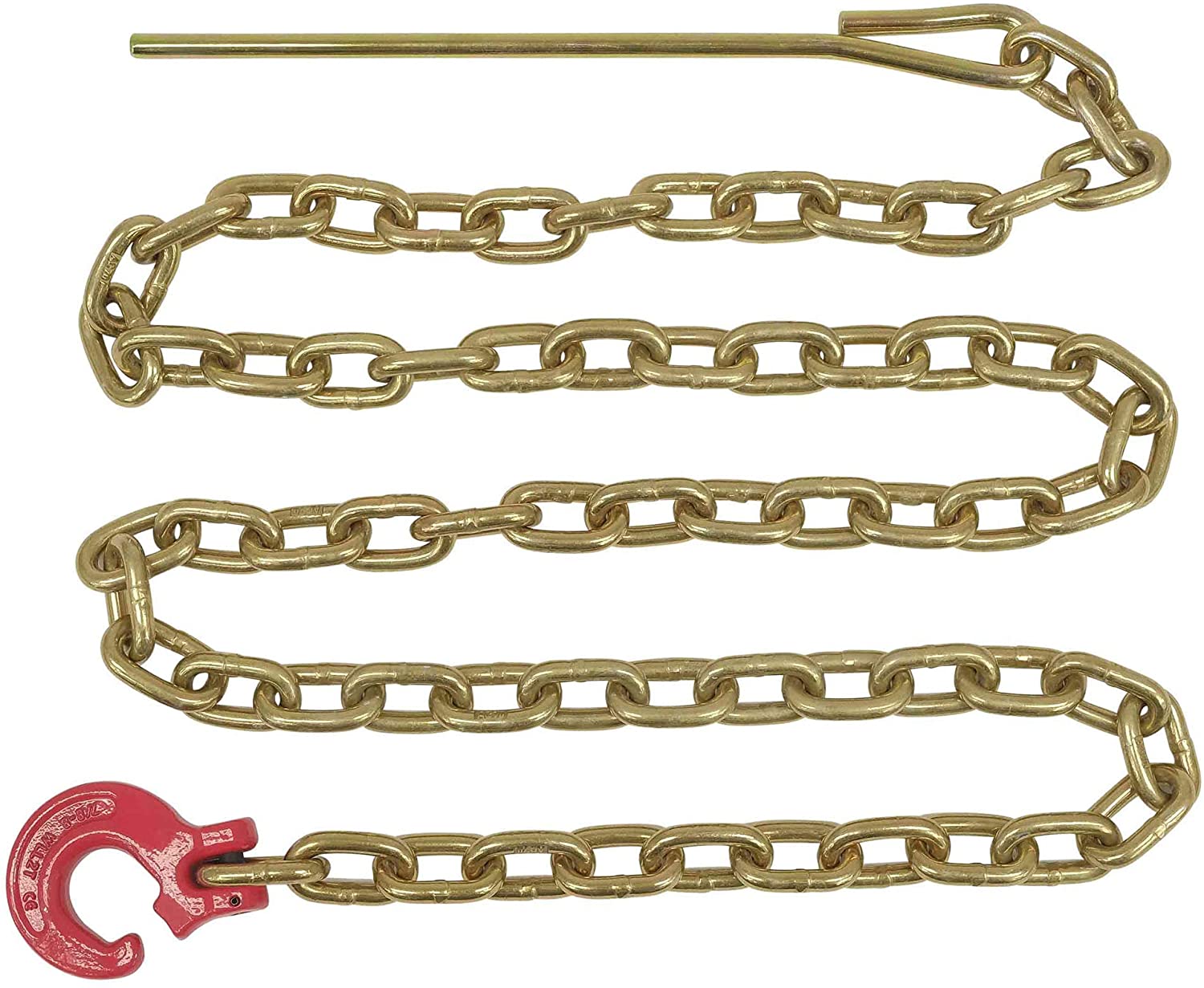

2. Choker Chain

If you want to hook up to a sharp object or another vehicle, you can use a choker chain. However, choker chains are not ideal for hooking into trees.

Buy The Choker Chain On Amazon

3. Tow Hooks

Tow hooks are secured on your truck’s frame, so you could attach straps, wire hooks, and chains.

4. Hook Strap

To avoid injuring your fingers, a hook strap is used to keep off your fingers from the fairlead while the rope is drawn in.

5. Snatch Block

A snatch block serves two purposes; improve the winch’s torque or pulling power and help you to adjust the pulling direction without disrupting the wire rope.

Buy The Snatch Block On Amazon

6. Clevis aka D Shackles

If you want to safely connect rigging straps, looped ends of cables, tree trunk protector and snatch blocks, a D shackle will come in handy.

Buy The Clevis aka D Shackles On Amazon

7. Tree Trunk Protector

Since you will probably be using a tree as an anchor point, you will need a tree trunk protector to preserve a living tree. Typically, the straps used are made of tough, high-grade nylon.

8. Recovery Strap

Don’t let the name fool you; a recovery strap is not intended to be used in a winching operation because it can stretch like rubber and cause serious damage if the rigging goes south. Instead, a recovery strap is used to ‘snatch’ out a jammed truck.

9. Heavy Blanket Or Winch Line Dampener

If you’re using a steel cable, you will need a winch line dampener to absorb energy and prevent the cable from recoiling if it breaks under tension. Alternatively, you could use a heavy blanket.

Buy The Heavy Blanket Or Winch Line Dampener On Amazon

10. Winch Line Extension

If you’re stuck and the anchor point is too far for your rope, you could use a winch line extension to increase your range.

11. Toolbox

Of course, you will probably require a few tools such as pliers, screwdrivers, hand wrenches, wire cutters, duct tape, connectors, electrical tape, automotive electrical wire, and an extra solenoid.

12. Shovel

If you’re stuck in mud, sand, or snow, you will definitely need a shovel to make it easier to recover your truck. While you’re at it, bring an axe and a Hi-lift jack.

13. Back-up Parts

Just in case something breaks, you should have a backup plan. For that reason, be sure to carry an extra snatch block, shackle, remote control unit, wire rope, and a winch hook.

14. Battery

If you’re using an electric winch, you will obviously need a battery to operate. However, you will need to bring a battery with the recommended rating as specified on the winch’s manual. Also, don’t forget some booster cables.

Winch Installation

Every winch installation is different depending on the type of winch that you possess. Remember, we have the hydraulic and electric winch which all use different installation techniques.

Not to mention, you have to consider if your bumper can support an integrated or non-integrated winch. Here is a piece of advice; if your truck is fitted with aftermarket bumpers, we suggest a non-integrated winch.

Otherwise, we highly recommend having your winch installed by a professional mechanic or a dealer. It probably won’t cost you more than $200, but even if it does, that money is nothing compared to how much you would lose if you had a serious injury due to a botched installation.

However, if you’re an expert and decide to do it yourself, make sure that you follow all the instructions on the winch’s manual. If your stock bumper is not enough to support a heavy winch, you ought to replace it.

Pretensioning The Cable

After installing the winch, you need to pretension the cable; otherwise, the rope could pinch itself when it’s time to unspool it and possibly cause wear and tear.

Pretensioning the cable should be done immediately after installation or before you go out on your off-road adventures.

So how is it done?

Step 1:

Find a flat location and park your truck at a distance where you can run out the entire length of the winch rope.

Step 2:

Disengage the clutch on the winch so you can free spool.

Step 3:

Pull out the winch cable until there are 5 wraps left on the drum. However, if you’re using a synthetic rope, spool it out until you’re left with 10 wraps on the drum.

Step 4:

Engage the clutch and fasten the hook end of the cable to a stable anchor point.

Step 5:

Go back to your truck, and reverse it until the cable stretches out; it should be tight, but not too tight.

Step 6:

Stabilize the wheels, set the gear in park, engage the handbrake and turn off the vehicle.

Step 7:

While you’re standing at least 8 feet away, use a remote control to power the winch until the extra loose rope is sucked into the drum.

Step 8:

Turn off your winch via remote control. Inspect if the cable is properly aligned on the drum and make sure there is no space between each coil. If you notice any inconsistency, you can carefully push the winch cable to the side (but wear gloves).

Step 9:

Switch on the truck, put the gear in neutral, disengage the handbrake and step on the brake pedal moderately.

Step 10:

While you’re in the truck, power the winch via remote control so you can feed the rope via the drum.

Step 11:

Slowly winch the vehicle until you’re about 6 feet away from the anchor point.

Step 12:

Turn off the winch via remote control.

Step 13:

Slowly take your foot off the brake pedal, engage the parking brake, put the gear in park, and switch off the vehicle.

Step 14:

Exit the vehicle and inspect to confirm if the winch cable is evenly wrapped around the drum. If it has sunk on the lower layer, you need to repeat the procedure until the rope has wrapped around the drum uniformly.

Step 15:

If the winch cable is correctly wrapped around the drum, unfasten the hook end of the rope from the anchor.

Step 16:

Activate the slowest speed setting on the remote control so you could slowly feed the cable back onto the drum.

Step 17:

Attach the hook to its designated mount on the vehicle.

How To Use A Winch

Before You Pull

Step 1:

For starters, you have to wear high-quality leather gloves, especially if you’re dealing with steel cable.

Step 2:

Connect the remote control and if it’s wired, make sure the cord doesn’t swing in front of the winch.

Step 3:

Slowly spool out the winch rope via the remote control, and when there is enough slack to release the winch, hook off its mount point.

Step 4:

Disengage the clutch so you could free spool.

Step 5:

Scout for a suitable anchor point that is strong enough to hold your vehicle. It could be a large tree, boulder, stump, rock, or another vehicle. If possible, choose an anchor point that is on an almost direct angle towards your truck.

Step 6:

Hold the winch hook and pull the cable to the anchor point. Make sure that you maintain tension in the rope.

Step 7:

Put a tree trunk protector or choker chain around the anchor point to secure it.

Step 8:

Bind the clevis or D shackle through the loops on the tree trunk protector or choker chain.

Step 9:

Keep the tree trunk protector as close to the ground as possible and attach the winch rope hook through the clevis or D shackle.

Step 10:

Go back to the winch and lock the clutch.

Step 11:

Stand at least 8 feet away from the winch and slowly wind the cable back into the winch via remote control. Press the remote control button until you notice some tension on the cable.

Pulling Out The Truck

Step 12:

Inspect the wire rope on the drum but don’t touch it. The cable should be evenly wrapped around the drum. If you properly pretension the cable, it shouldn’t be a problem.

Step 13:

Put a blanket over the cable wire or rope. This is important because the last thing you want is for the rope to snap and start swinging. However, the blanket will absorb energy.

Step 14:

If there are people close to your winching zone (vehicle, cable, or anchor point), tell them to stay away as far as possible.

Step 15:

Enter your truck and close all the windows. If your remote control is wired, you can open a small opening in your driver seat window to let it in.

Step 16:

Turn on the stuck vehicle, engage the gear in a neutral position, release the handbrake, and lightly step on the brake pedal.

Step 17:

Start winching via the remote control. Do it slowly and steady until your truck is off the ground and on a stable surface.

Step 18:

Once you’ve recovered the vehicle, turn off the winch via the remote control. Next, slowly take your foot off the brake pedal, engage the parking brake, put the gear in park, and switch off the vehicle.

After You’ve Pulled

Step 19:

Remove the winch rope hook from the D shackle or clevis.

Step 20:

Slowly rewind the winch rope to the drum via the remote control. Make sure the cable is evenly aligned on the drum with no space between each coil.

Step 21:

Once the cable has been fed into the winch drum, attach the hook on its mount and disconnect the remote control.

Winching Techniques

Here is the general rule; your truck should be on a straight angle to the anchor object during a winching operation. The purpose is to prevent the rope from rolling on one side of the winch drum so you wouldn’t damage it.

However, if you’re using another vehicle as an anchor object and there is not enough space to park in front, you could use a snatch block.

Basically, a snatch block will enable you to change the pulling angle to 90 degrees without disrupting the winch cable. All you need to do is pass the winching line through the snatch block and direct it towards a different direction; of course, the snatch block needs to be attached to the D shackle on the tree trunk protector.

Other than that, you could use a snatch block to perform a double line or a triple line pulling technique. For a double line technique, you pass the winch line through the snatch block connected to the D shackle on the anchor point and take it back to your vehicle’s frame to hook it up.

A triple-line winching technique is more complicated; it’s like a double line technique, but instead of stopping at the tow hook on your truck, you run the winch line back to a different anchor object up ahead.

Winching Safety Precautions

If you’re not careful, a winch-related accident could cause serious injury and sometimes death, especially if it snaps when loaded.

However, there are a few safety precautions you can follow to ensure that doesn’t happen. What are we talking about?

1. Always wear high-quality gloves during a winch use.

2. When choosing a tree as an anchor point, avoid dead trees because they could easily break.

3. Make sure you wrap a tree trunk protector as close to the ground as possible on a tree anchor point.

4. After you’ve secured the winch line, put on a heavy blanket over it. This helps to absorb the energy and prevent injury if the rope snaps.

5. Never attach the winch rope to itself on an anchor point. The winch line pull hook should be attached to the D shackle.

6. When attaching the winch cable hook to the D shackle, make sure you hook up instead of downwards. By doing so, if the hook fails, the cable will move to the ground.

7. Always inspect the winch cable before you go out on an off-road trip. If you notice any signs of rust, damage, or wear and tear, you should have it replaced.

8. Don’t stand close to your winch motor or cable when pulling your vehicle. You should be inside your truck and operate the winch via remote control.

9. When winching your truck, you should put the gear in neutral, release the handbrake, and put your foot on the brake pedal. Don’t attempt to winch while the engine is off or the truck is in park.

10. Don’t re-spool the cable using your hands close to the fairlead.

11. Never use your winch as a yank or towing strap.

12. To avoid overheating an electric winch, take a short break after 45 or 60 seconds. If you’re winching continuously and aggressively, you risk overheating the winch wiring components and drain your vehicle’s battery.

13. If somebody on the outside is helping you to recover your truck, he/she should stand clear at a safe distance and communicate via radio or hand signals.

14. Clean your winch, wire rope, and remote control regularly using a towel or rag. Also, you could apply light oil on the winch cable and hook to prevent rust and corrosion.

Common Q & A

Q. How do you calculate winch size?

A. It’s simple, just multiple the weight of your truck by 1.5. That means, if your vehicle is 10,000 pounds, you should choose a winch size that can pull 15,000 pounds.

Q. How much weight can a winch pull?

A. Most heavy-duty winches for trucks in the market can pull up to 20,000 pounds.

Q. What do winch numbers mean?

A. The designated numbers on winches usually refer to the power ratio. As a general rule, the higher the number, the more the power.

Q. How do you increase the capacity of a winch?

A. You can increase the pulling power of your winch by using the double line or triple line winching technique.

Q. How do you calculate pull load?

A. To calculate the pull load, you can divide the distance to the anchor point by the winch line speed to get an estimate. That means, if you need to pull 100 feet and the winch drum draws in 10 feet of rope per minute, you will need 10 minutes to cover the distance.

Conclusion

Remember, every situation is unique and different when you’re stuck and you need a winch to recover your truck. Whatever you do, it’s important to take your time, evaluate the situation and prioritize safety above everything else.

Besides that, you should practice how to use a winch as much as possible so that when the time comes to actually operate it, you won’t be left clueless. Can you handle it?